Grain silo ventilation is essential to preserve crop quality, prevent mould and infestation, and avoid economic losses. It regulates temperature and humidity, limiting heating and condensation, which can compromise grain safety and preservation, making the grain unfit for consumption.

Step ventilation is a technique commonly used to efficiently cool grain stored in silos. This method involves gradually lowering the temperature of the grains in successive stages, maintaining constant temperature levels for defined periods.

At Javelot, we have developed an automatic control mode to optimise ventilation performance. This automated mode identifies the ideal ventilation periods by taking into account real-time weather conditions and the temperature differential between the inside of the silo and the outside.

Ventilation is triggered automatically when the temperature of the outside air is between 8 and 20°C lower than the hottest point of the grain. This differential can be adjusted according to the equipment and heating in the ventilation shaft.

This approach ensures maximum efficiency, reduces energy consumption and optimises grain preservation, offering a sustainable and cost-effective solution for storage organisations.

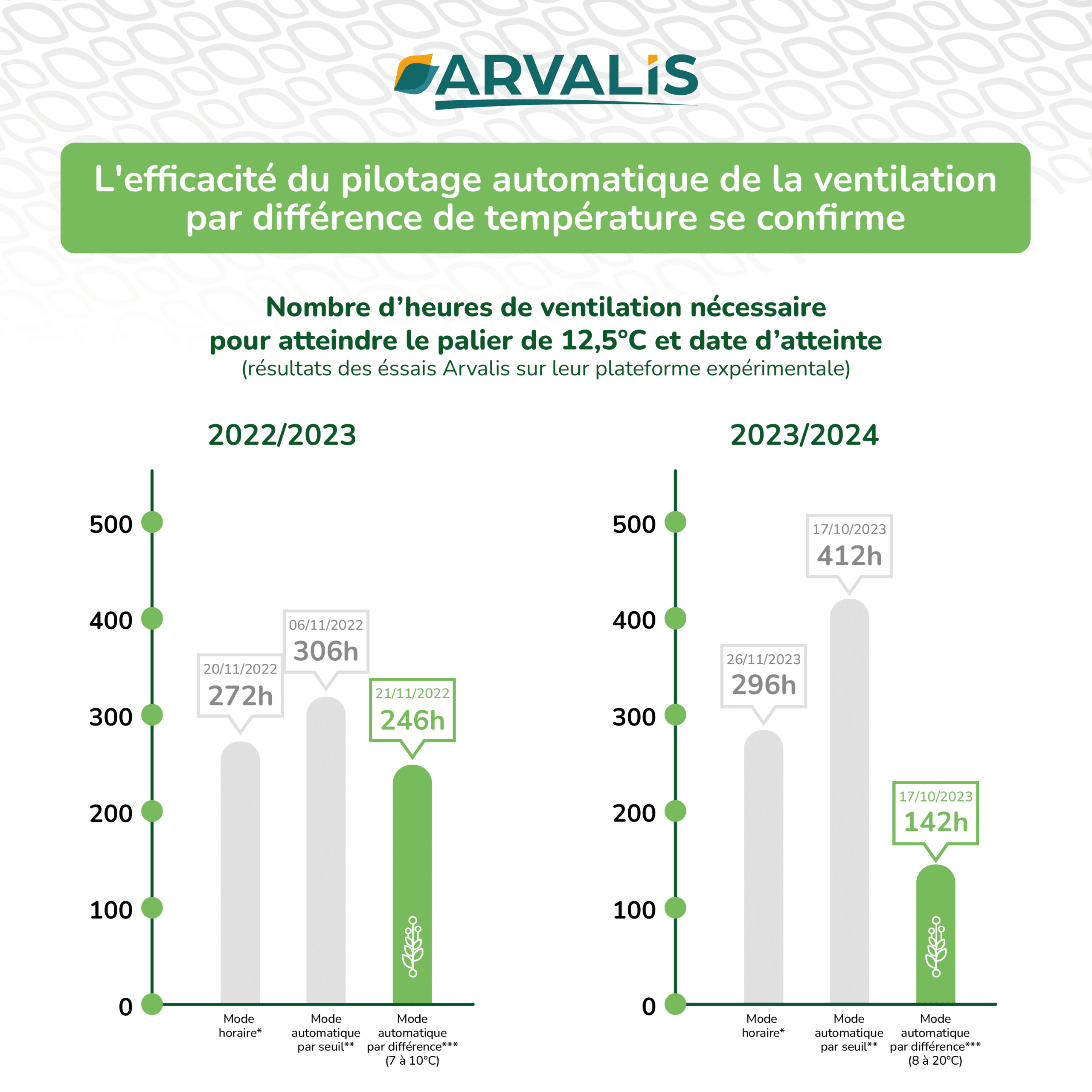

*Hourly mode: manual activation based on weather forecasts, with fixed ventilation times.

**Automatic threshold mode: automatic activation when the outdoor temperature falls below a predefined threshold.

***Automatic difference mode (Javelot system): activated according to the difference between the warmest temperature of the grain and that of the outside air, with a target difference of 7 to 10°C for the first year and 8 to 20°C for the second.

Trials currently being carried out by Arvalis on the Boigneville experimental platform (91) confirm the effectiveness of Javelot automatic control by temperature difference, compared with the conventional thermostat and hourly control.

Initial tests show that the Javelot system consumes the fewest hours of ventilation to reach the target temperature of 12.5°C.

Over the 2023/2024 campaign, it will enable a significant reduction in operating hours: -65 % compared with the conventional thermostat and -52 % compared with hourly operation, while still achieving the target temperature on the same dates.

The study confirms that the Javelot system optimises grain cooling, reduces energy consumption and ensures more efficient and responsive control in the face of temperature variations.