Quality, safety, maintenance, Javelot launches a solution for digitizing procedures dedicated to storage sites

Javelot is launching a new module that will enable storage organizations to digitize all processes linked to quality/safety and silo preventive maintenance. Co-constructed with several of its customers, the aim is to provide greater fluidity and traceability in the proper execution of procedures, and to facilitate coordination between teams, all in the service of operational excellence and compliance.

Within a silo, hundreds of readings, checks and preventive maintenance actions must be carried out throughout the year to ensure the integrity of storage facilities, guarantee the quality of raw materials and the safety of personnel: cleaning, dust removal, checking elevators, conveyors, lubrication, washing, engine checks, checking and cleaning filters...

All these points are listed in numerous procedures, many of which are mandatory by law.

Most often, these checks and records are carried out by field operators (silo managers, technicians, etc.), usually by hand, before being recorded in a binder or shared Excel file. These tasks are time-consuming, potentially a source of errors, and above all difficult to monitor, in the absence of data centralization. A real headache for all teams: for operators in the field, it's hard to see clearly what needs to be done, and when... and for management teams, it's hard to keep track of how procedures are being carried out. Not to mention the difficulty of gathering data for health inspections and other regulatory audits.

That's why Javelot is launching a new connected solution that digitizes all procedures linked to quality, safety and preventive maintenance at storage sites, and ensures better traceability.

The fruit of co-construction with Store Organizations

This connected solution was co-constructed with various storage organizations, to provide the best possible response to the concrete problems encountered in the field. For example, our teams worked with customers to identify all the procedures and control plans in force at their storage sites that could be digitized. We found that many of these were fairly standard, although there may be some variations and specificities from one OS to another.

Javelot has therefore come up with a connected solution for identifying and monitoring procedures, grouping them by theme and within a library that customers can then adapt and parameterize to their own specific requirements.

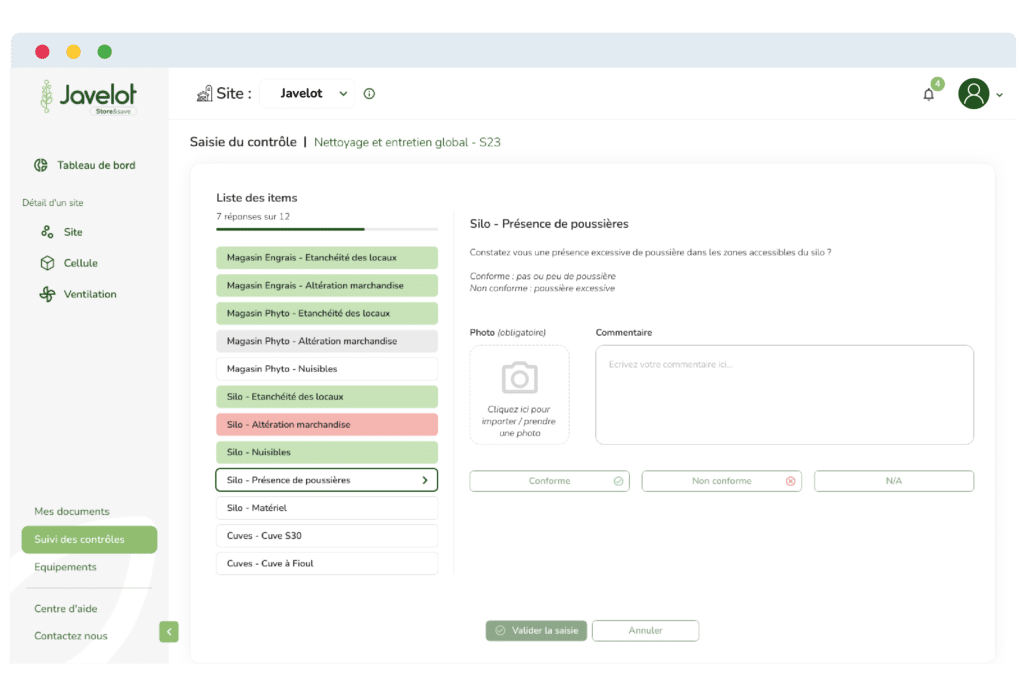

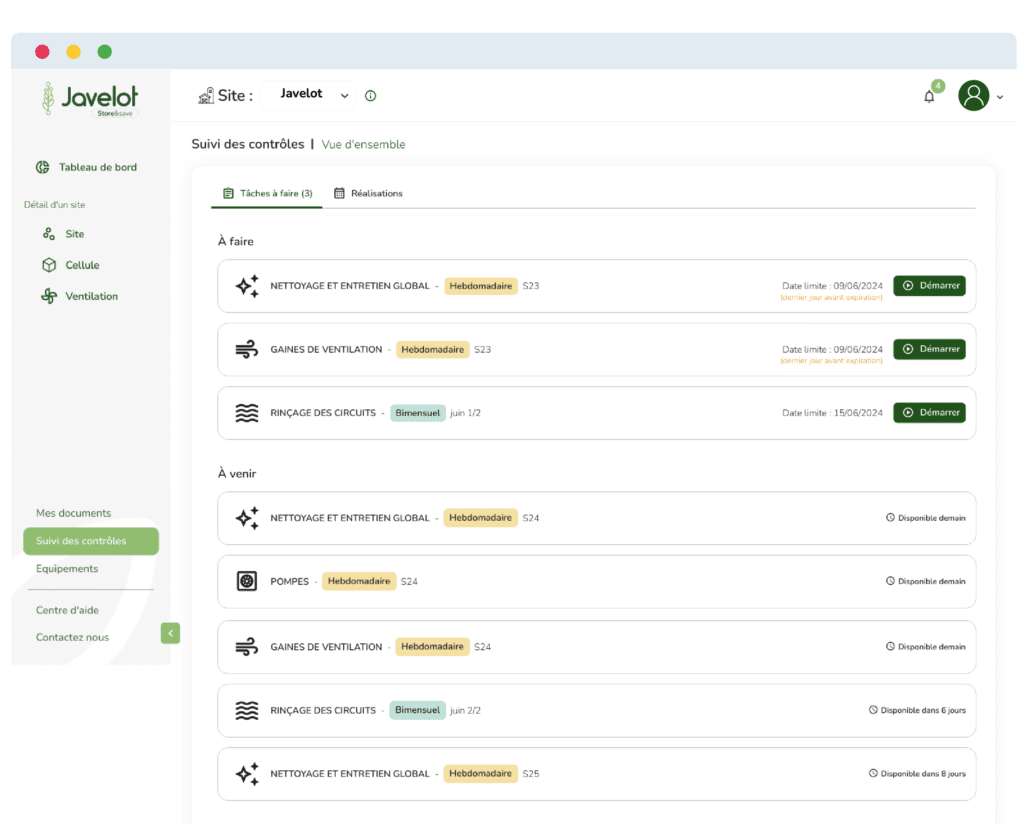

For example, to monitor the presence of dust in silos and fertilizer stores: the quality manager or grain business manager can configure the tool to define how often a check should be carried out, whether it should be accompanied by a photo, and so on. For his part, the operator responsible for carrying out the checks can do so in situ, directly from his tablet or smartphone. He can take a photo if required, load it directly into the tool, enter the dust level zone by zone... and the application reminds him of all the actions to be carried out during the week, and any omissions. If necessary, he can also make comments and pass on information, thus ensuring better communication between the field and management.

Hundreds of items of information are centralized on the application, at predefined frequencies throughout the year. And more globally, dashboards provide an overview of the progress of different procedures. It's a win-win situation: field teams are fully involved in operational performance, and management teams find it easier to coordinate operations. They can also provide better traceability to supervisory authorities and customers (particularly for certified supply chains).

Responding to growing turnover in silos

All the storage organizations we work with mention the growing problems of staff turnover, recruitment difficulties, the need to use replacement services... and therefore the increasing difficulty of ensuring operational continuity at storage sites," explains Félix Bonduelle, Javelot's Managing Director. The issue of regulatory compliance also comes up regularly.

That's why they ask us to work on digitizing their processes. These are classic industrial issues, so it's only logical that the sector should resort to digital tools, as is the case throughout industry today.

At Javelot, we have built this new module in the continuity of previous connected solutions, with the aim of digitizing the entire post-harvest grain data chain, at the service of both operational excellence and business attractiveness.

It will be an optional addition to Javelot's “Store&Save” solution, with the aim of integrating all the operational issues encountered on storage sites into a single platform." However, it can be sold independently. The aim is to market it before the end of 2024, so that storage organizations can use it for the 2025 campaign.

Press contact : Laetitia Munoz, Presse & Cie - lmunoz@presse-cie.com – 06 20 49 90 39