Thanks to a wide range of thermometry probes and connected equipment, Javelot's hypervision and optimisation platform for the grain storage conditions, Store&save, is accessible to all storage facilities, independent of their initial level of equipment.

"Flat storage, vertical silos of all sizes, sheet piling silos, silo bags ... We are able to equip absolutely all types of storage", explains Brice Faucret, Technical Director of Javelot.

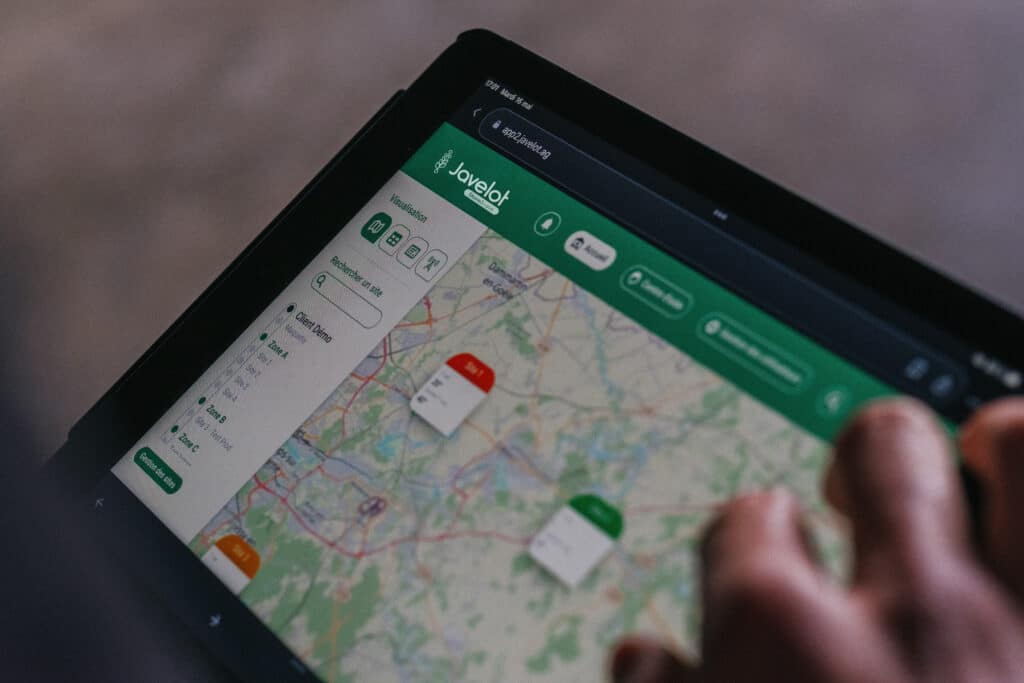

Our aim is to make our storage optimisation app, Store&save, accessible to all storage facilities, regardless of their storage type, whether they are already equipped with analogue or connected thermometry probes or not and regardless of their network coverage ... Javelot adapts and offers you the best solutions for centralising all your storage data on a single hypervision platform, Store&save. This monitoring aspect is one of the major advantages of our platform, compared with other solutions where data is stored locally. From a tablet, a smartphone or a computer, you can keep an eye on everything that is going on in your silos on different sites, in terms of thermometry, ventilation and traceability and monitor the overall performance of the storage operations.

Our equipment for monitoring the silo temperature data

- “Flat" probes for flat storage:

The Flat'Javelot is a mobile, flexible, ready-to-use probe that is directly inserted into the grain. This 2m probe is suitable for all flat storage, the maximum recommended pile height being: 6m. It is inserted directly into the pile of grain (1 probe per 300 t of grain is recommended).

- “Verti” probes for vertical cells :

The Verti’Javelot is a custom-made probe that fits all vertical silo cells, with no height limits. The sensors, positioned all along the flexible cable, guarantee temperature measurements on all levels of the grain. These probes are installed by us.

- Connection system for silos which are already equipped with thermometry probes: :

The Connect’Javelot allows you to connect your existing analogue and digital probes in your storage facilities, in order to digitalise the information and send it to the platform. The aim is to have a hypervision of what is happening on all your sites, regardless of the technology of the probes.

The temperature readings from each probe are transferred every two hours to Javelot's servers via a low-speed network (Sigfox), offering a complete traceability throughout the whole storage period.

Our "Venti" units for ventilation control and energy consumption optimisation

The Venti’Javelot, is a solution that can be adapted to ventilators of any power and to any ventilation system. It allows you to control your ventilation, triggering it only during the right ventilation periods, when temperatures are ideal, without having to go on site and it starts automatically. The automated ventilation mode has proven to be more efficient than other functioning modes. Nonetheless, the tool is flexible and allows switching back to manual or programmed mode at any time, according to your needs.

The ventilation data is also uploaded in real time to the hypervision platform, providing traceability of your ventilation periods, over any storage period and for any of your sites.

Our day-to-day support makes all the difference: :

The technical coordinators of Javelot go to your site and carry out an audit in order to determine the size of your equipment requirements, and in particular the cellular connectivity dedicated to low-speed, low-cost and low-energy consumption communications.

Thanks to our available and responsive team, the equipment maintenance and daily monitoring and support are included.

Our customers say it best!

“The versatility of the Javelot solutions adapts to all our storage sites: sheet piling silos, vertical silos, cylindrical silos, flat storage ...” Alexandre THOUIN - Centre Ouest Céréales

“At a glance, I can see what is going on on my sites. We have a lot of sites without permanent staff. Javelot makes it possible to monitor the temperature remotely and manage ventilation as effectively as possible.” Didier RENOU - Océalia